Hurry up to buy a subscription for full access

SCANDOO

Scan around

the world

the world

Catalogue

Brands

Services

Support

About us

10080831 3D models

+10000

8759458 drawings

+20000

All design data (3D-models and drawings)

Machinery

Refrigeration and cryogenic equipment

Packaging and food equipment

Petrochemical

Transport

Mining and processing

Order 3d scanning first order -20% discount

Didn't find the item you need?

Our agent is already on his way to you to order what you need.

3D Scanning

3D scanning is a technology used to capture the physical shape and dimensions of an object or environment. It works by using lasers, structured light, or photogrammetry to collect detailed spatial data.

This data is then used to create a digital 3D model that accurately represents the original item. 3D scanning is widely used in industries such as manufacturing, engineering, healthcare, and art for design, analysis, and reproduction purposes.

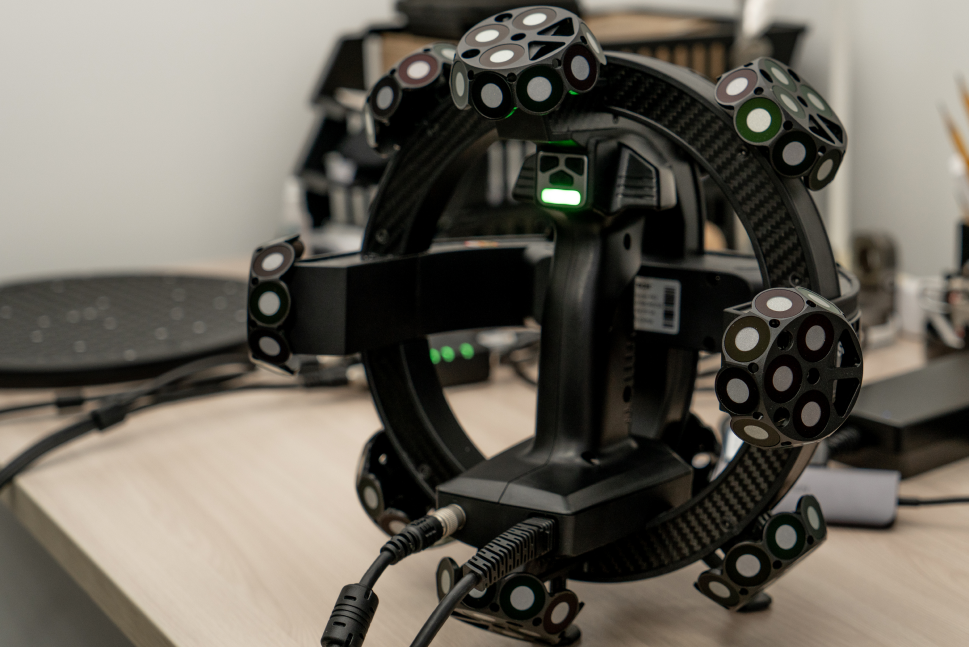

TrackScan-P42 series scanne

TrackScan-P42 series scanner, scanner accuracy up to 0.025 mm, scanning without pasting the object with marks, scanning large-sized objects over 10 m. Checking the assembly of large-sized products.

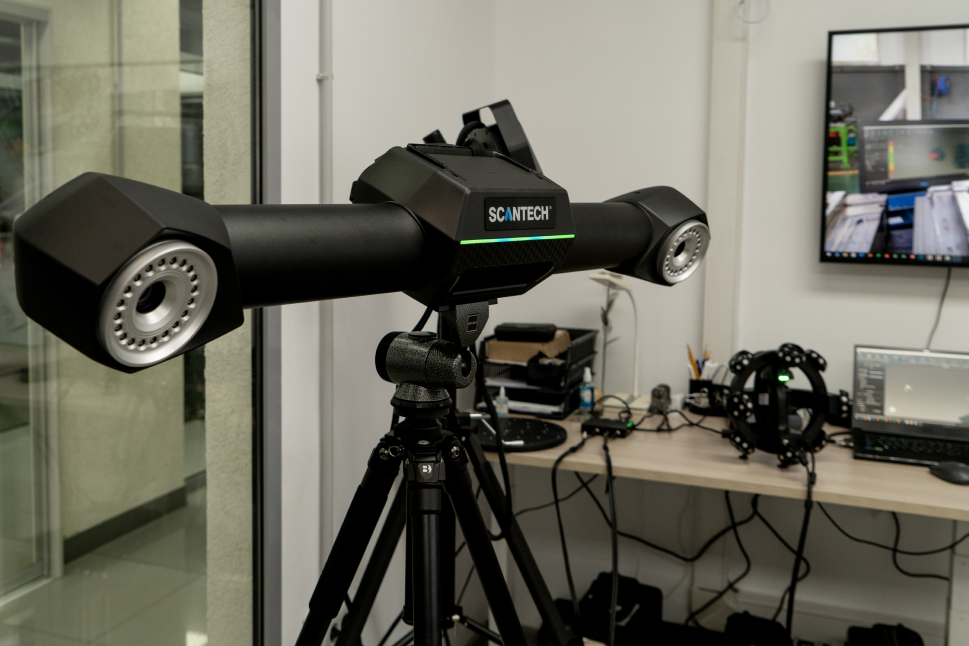

KSCAN

Magic series scanner, scanner accuracy up to 0.020mm+0.030mm/m, with a photogrammetry system that allows minimizing the accumulated volumetric error when scanning large-sized parts.

Control of geometry of large-sized objects

3D scanners have no restrictions on the size of the object being examined. This completely replaces classic control tools and reduces time and money costs.

Metrological accuracy of 3D scanners

Scanner series SIMSCAN, scanner accuracy up to 0.020mm+0.035mm/m, for parts with overall dimensions up to 500x500x500, accuracy is achieved up to 0.016mm

Our experience

Point Cloud Generation in 3D Scanning

3D scanning captures an object’s surface geometry using lasers, structured light, or photogrammetry, creating a point cloud — millions of precise XYZ coordinates.

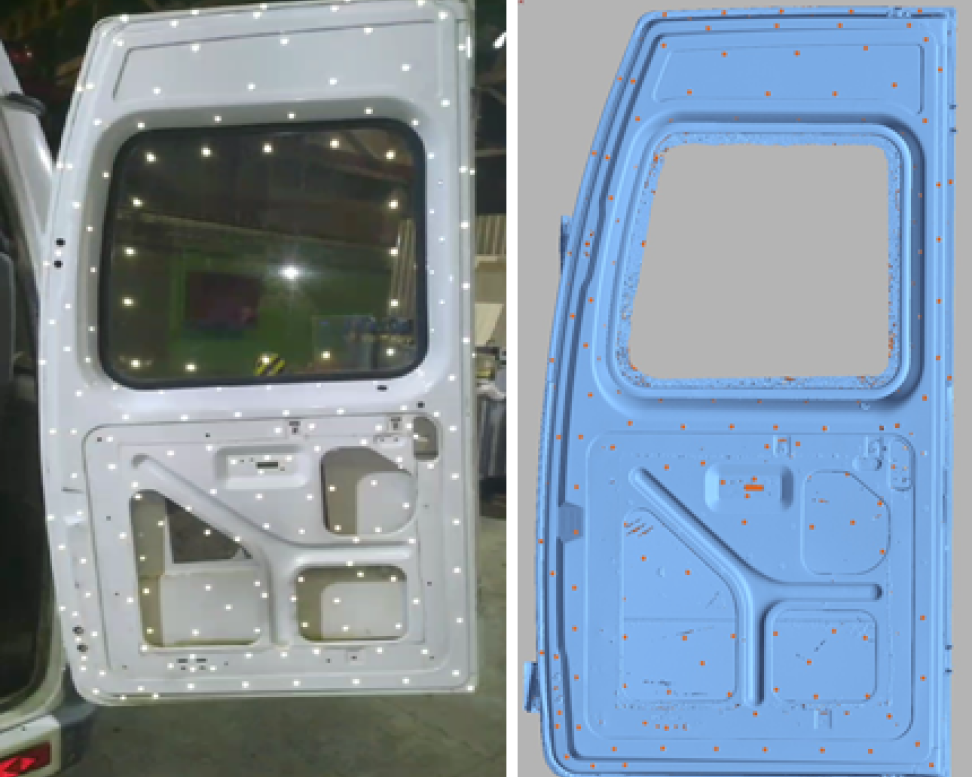

Automotive industry

The technology creates precise digital models of parts, bodies and prototypes, reduces production times, identifies defects and allows design to be adapted to individual requirements.

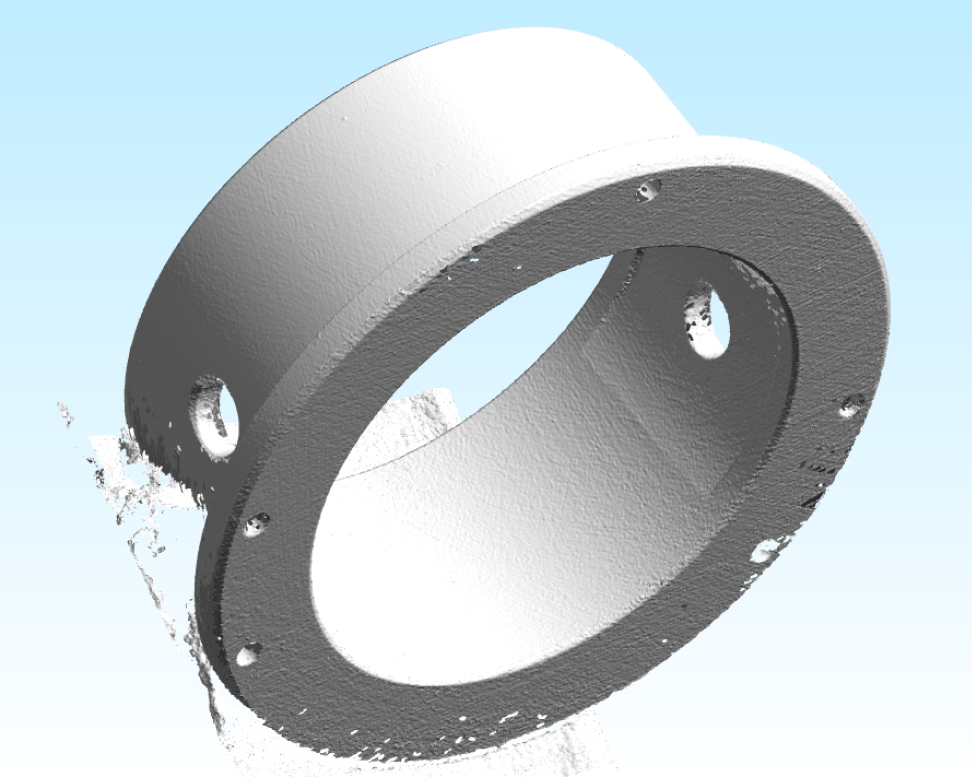

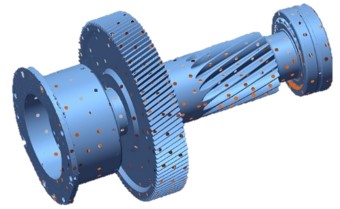

Reducer

Allows you to visualize geometry, perform engineering calculations (loads, thermal conditions), test the assembly and identify collisions. Here is our experience with gearboxes in machinery