Hurry up to buy a subscription for full access

SCANDOO

Scan around

the world

the world

Catalogue

Brands

Services

Support

About us

10080831 3D models

+10000

8759458 drawings

+20000

All design data (3D-models and drawings)

Machinery

Refrigeration and cryogenic equipment

Packaging and food equipment

Petrochemical

Transport

Mining and processing

Order 3d scanning first order -20% discount

Didn't find the item you need?

Our agent is already on his way to you to order what you need.

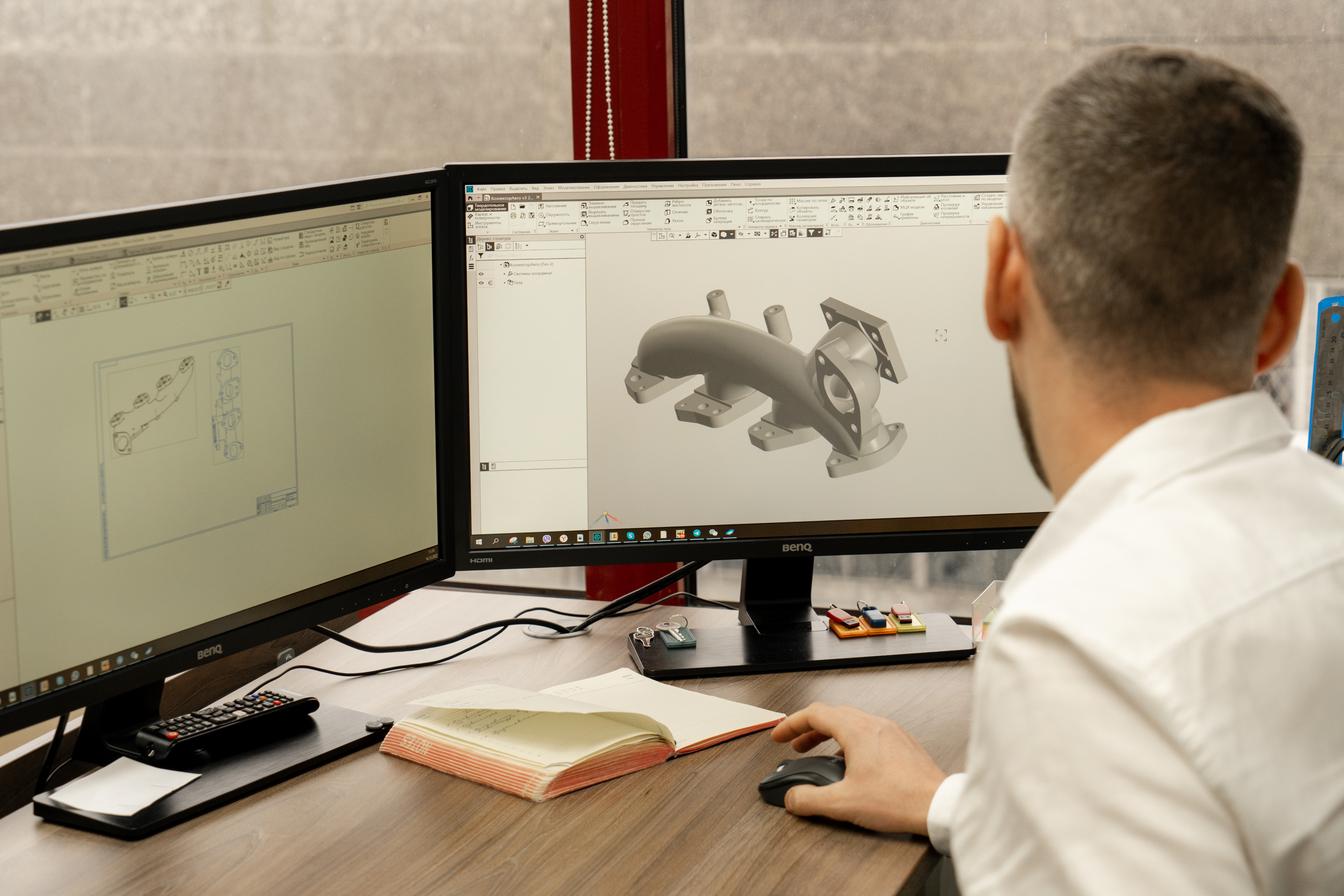

Reverse Engineering

Reverse engineering is the process of analyzing and deconstructing an existing product to understand its design, structure, and functionality. This technique is often used to recreate, improve, or redesign components when original documentation is unavailable.

In combination with 3D scanning, reverse engineering allows for precise digital reconstruction of physical parts, making it valuable in industries like manufacturing, automotive, aerospace, and product development.

Aviation Reverse

Reverse engineering is essential for the aviation industry to analyze advanced technologies, accelerate development, reduce costs, and enhance competitiveness...

100% analysis

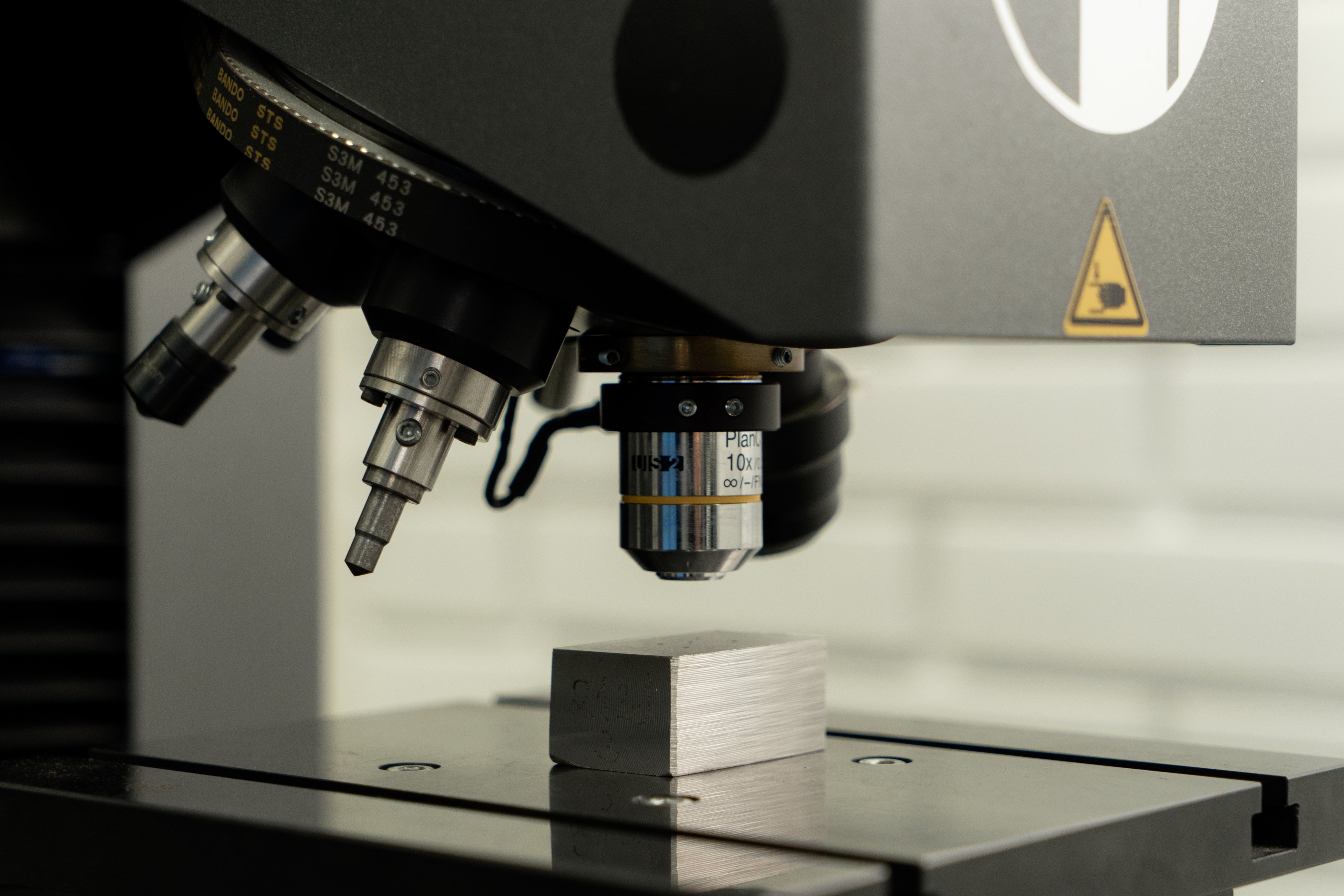

Necessary measuring instruments, devices and equipment. Classic hand measuring tools: calipers; micrometers; electronic profilometers; ultrasonic hardness testers...

All collected information collected by engineers

About the reverse engineering object measurement map (name, article numbers, PMI express analysis, hardness and roughness measurements)

Scanned 3D point cloud, operating manual, etc. is transferred to the design department for further processing, modeling and development of design documentation.

Our experience

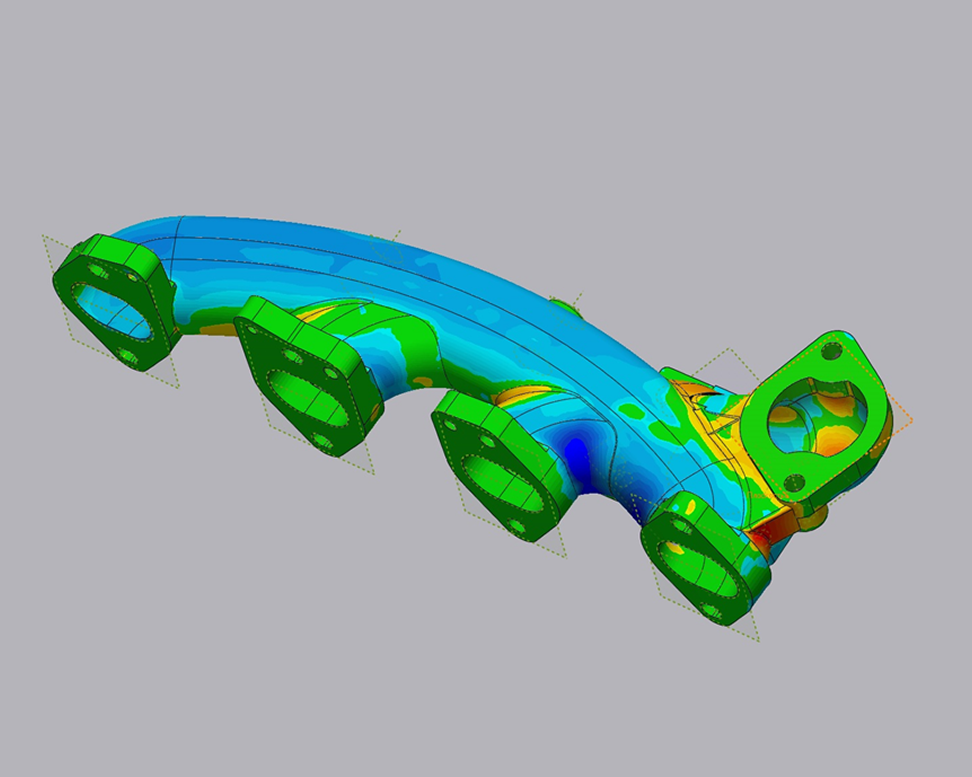

Automotive industry

By performing quality control of the product geometry with a reference CAD model, we can visualize the surface topography of positive and negative deviations, and then localize the defect for further analysis of the violation of performance.

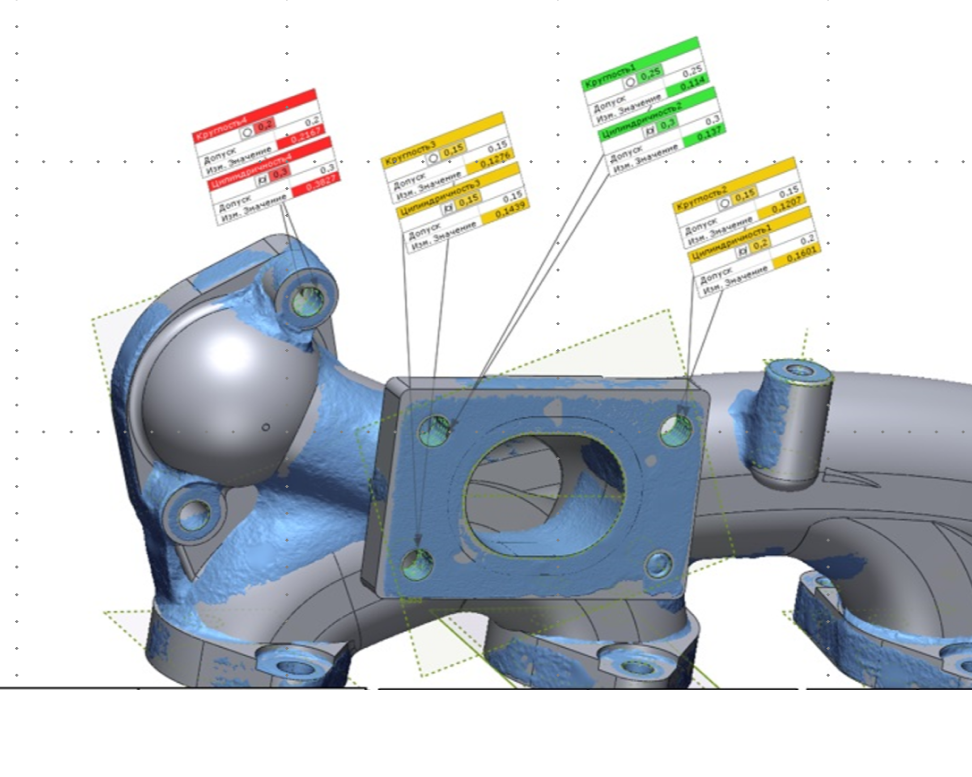

Crushing equipment, hydraulic cylinders

Technical support, quality control and assembly. A report visualization of the location of inspected forms and surfaces is performed, information about them in the form of a table with measured data for further analysis for assembly and joining of parts.

Modeling

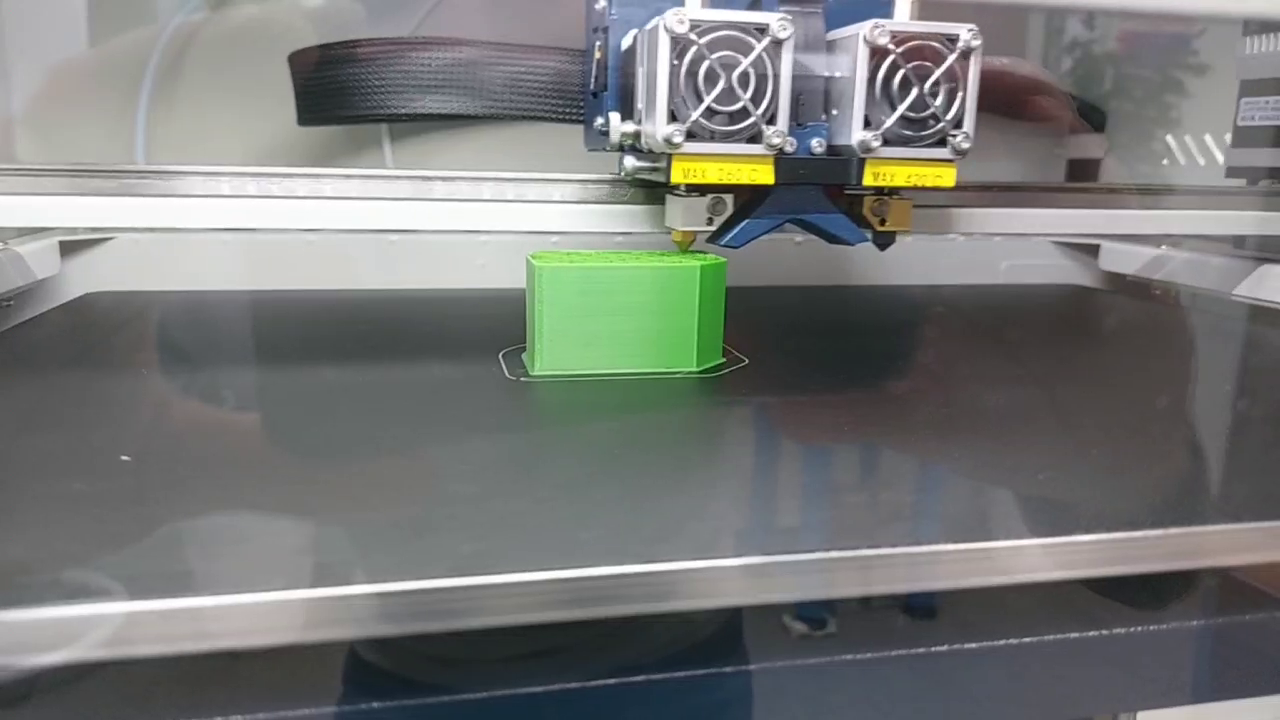

After reverse engineering, we can print the resulting model on high-precision 3D printers for visualization and testing.